Knowledge and many years of experience allow us to answer many questions you may have about the processing of thermoplastics:

- How to design the product?

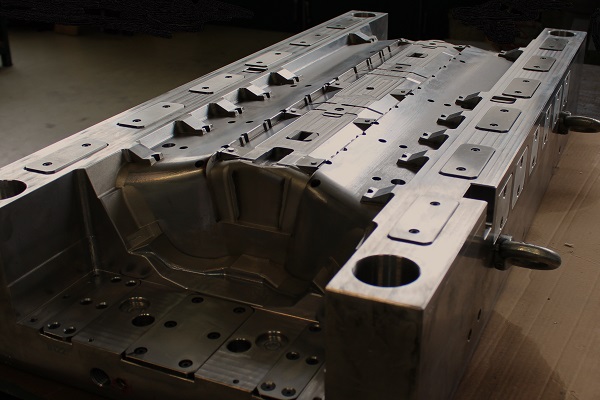

- How to build a quality and long-lasting tool?

- How to start and run a serial production process?

We are experts in consulting, designing and manufacturing single-component (1K) and multi-component (2K and 3K) tools for the processing of thermoplastics, as well as tools for various injection technologies such as Gas Injection Technology (GIT), over-moulding (hybrid injection) or in-mould tools.

We manage the project for you from the idea to the product and deliver the tool to you on a turnkey basis.

We:

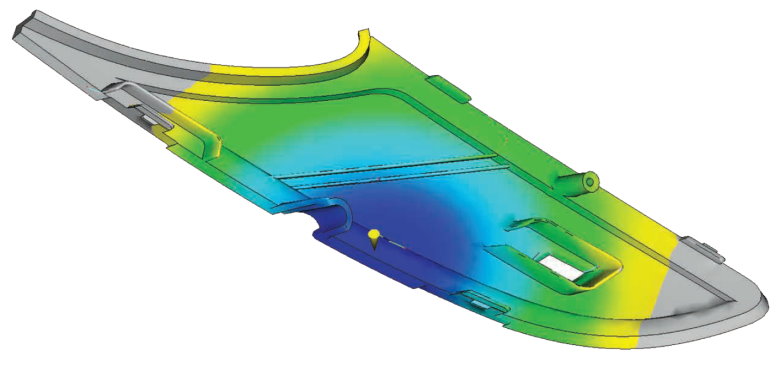

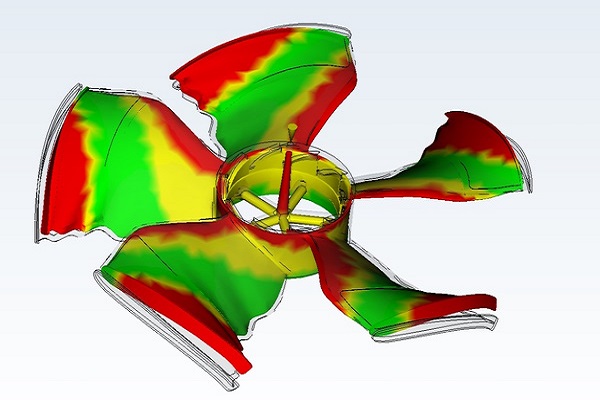

- technologically analyse your conceptual product (DMF and Mold Flow analyses including fill, warp, cool analyses),

- design the tool for its production,

- manage the production of tools,

- test the tool to check its correctness and the quality of the resulting product,

- check the functional and dimensional adequacy of the product,

- define the process parameters for production in serial conditions.

We also produce smaller series of products.

All this in:

- automotive,

- electro,

- furniture industry,

- household appliances,

- packaging and

- other technical products.