Tool and product measurements – 3D scanning

Our measurements are performed with ATOS Core cameras 3D scanning and data processing with the GOM Inspect Professional software. The cameras provide high accuracy.

The following steps are required for measurements

Preparation:

Because the product is viewed/scanned by the camera with its blue light, we must enable it to “see” the product. We make the product visible to the camera by applying reference dots and a thin layer of 3D scanning (anti-reflective) spray to get the highest possible scan quality.

The camera size choice:

Every camera size has different measuring area which allows us to measure products of various sizes – from a few millimetres to a few metres and very complex shapes.

Set up - camera calibration:

The measured object must be warmed up to a room/working temperature (very important on cold winter and hot summer days). We maintain the stable temperature in our measuring lab. We calibrate the camera before starting to scan.

Measurements:

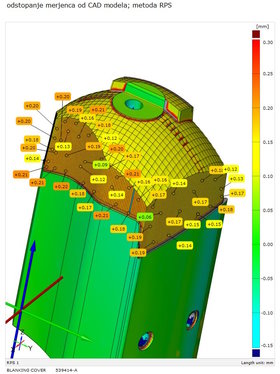

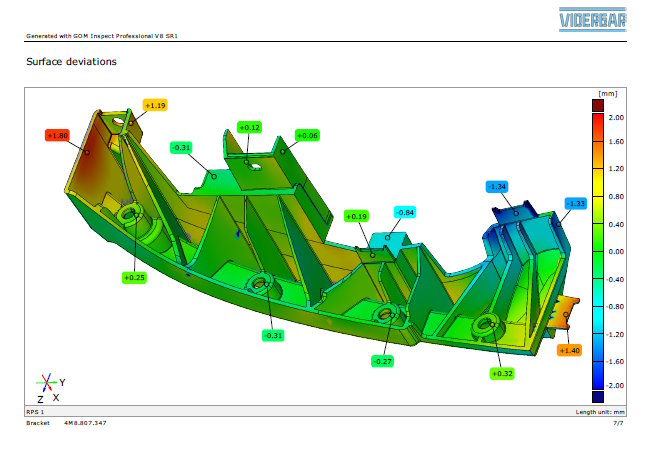

With scanning we capture the real shape of the product and compare it with its CAD model which is the desired state. With a simple report, we show the deviation of the actual product from its 3D model at critical points.

Based on the drawing we create a measuring program which allows us to measure the required dimensions. As a result, we get a measurement report.

For more information, do not hesitate to call or write:

Valentina Zorman

00 386 31 33 55 45

valentina@vidergar.si