Mold Flow analysis

is a computer-aided injection molding analysis of the plastic transformation process.

# Are you worried that your product might not meet high quality demands (due to aesthetic failures)?

# Are you in doubt what would be the most optimal type of injection system and where to place an injection point?

# Is the lead time short and you can not afford numerous tool try-outs through optimisation process?

Computer-aided injection molding analysis is a reliable support in the process of product and injection tool development.

It is the software that enables us to predict and to avoid potential failures in production process as well as product quality issues already during the development stage.

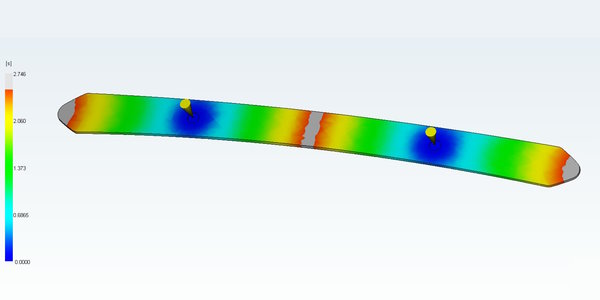

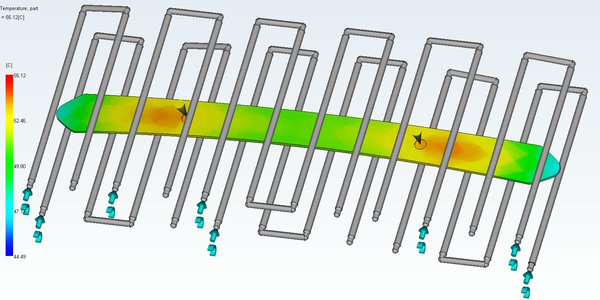

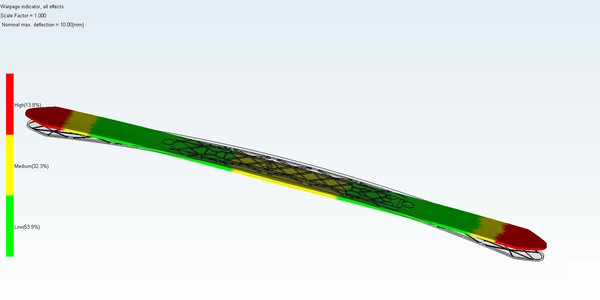

Simulations of fill, cool and warp give us insight into what is happening in the tool cavity during the injection process (a clamping force, a pressure and a fill time needed) as well as what the product quality is expected (aesthetic failures such as weld lines, sink marks, air traps, warpage...).

It is the base that allows us to:

- chose optimal number and position of injection points: we optimize a clamping force, an injection pressure, predict and if necessary, minimize aesthetic failures.

- calculate cooling time and gives us an insight into the critical zones of cooling system.

- calculate the deviations of the real product from its CAD model. We pre-warp the basic product design to compensate real product warpage.

- determine the injection time and the clamping force (the size of injection machine).

If you are interested to get an advice for your product, do not hesitate to call or write:

Valentina Zorman

00 386 31 33 55 45

valentina@vidergar.si